Tel:0512-66958483

Email:engforlife-mkt@www.clrrmsjy.com

試劑/耗材

Reagents / Consumables

Gelatin Methacryloyl (GelMA) ;

EFL-GM-30/60/90

The kit includes gelatin methacryloyl and photoinitiator LAP.

All products in the GelMA range can be used in cell culture, biological 3D printing, tissue engineering, etc.

This product is for research use only and can not be used in humans.

Salesperson:Panpan Wang(EFL)

Phone:15335258233

Email:engforlife-mkt@www.clrrmsjy.com

Foreign distributor:ANR Technologies Pte Ltd

Gelatin is a natural biopolymer material obtained by moderate hydrolysis and thermal denaturation of collagen, which has a similar amino acid sequence to collagen. Gelatin side chain contains many active groups, such as amino group, carboxyl group, hydroxyl group, etc. The possibility of multi-site chemical modification makes gelatin favored by many hydrogel researchers.

Gelatin Methacryloyl (GelMA) is an alkene double bond modified gelatin, which can be quickly photo-crosslinked and cured into gel through UV and visible light in the presence of a photoinitiator. GelMA has the characteristics of both natural and synthetic biomaterials, with a three-dimensional (3D) structure suitable for cell growth and differentiation. GelMA has excellent biocompatibility and cell reaction properties, such as providing suitable cell adhesion sites and proteolytic degradation, which can replace artificial basement membranes or other natural collagen hydrogels. In addition, GelMA has good mechanical properties, and the 3D microscaffolds constructed by it have adjustable mechanical and chemical properties. GelMA has good thermosensitive gel properties and degradability, its mechanical properties can be adjusted, and can provide a variety of viscoelastic properties, which has been widely used in cell 3D culture, tissue engineering, bioprinting and other research fields.

The GelMA product from EFL team (EFL-GM series) has stable physical and chemical properties through strict raw material screening and quality testing. Since its launch, it has served hundreds of research groups in Harvard, Cambridge, MIT, Hong Kong University, Tsinghua University, Peking University, Zhejiang University, Jiaotong University and other domestic and foreign universities, and has been praised and recognized by domestic and foreign scientific research workers.

Cell culture, bio 3D printing, tissue engineering, etc.

Dry kit: room temperature, 3 months; 4℃, 12 months; -20℃, 18 months.

Fig 1. Synthesis reaction mechanism and NMR spectrum of GelMA

Fig 2. Rheological properties of GelMA: viscosity (shearing rate: 10rad/s, 37 ℃)

Fig 3. Rheological properties of GelMA: cooling and warming phase inversion temperature and gel strength G’ at 5 ℃(oscillation temperature scan: 40 ℃→4 ℃→40 ℃, 5 ℃/min, strain 1%, angular rate 5 rad/s)

Fig 4. Rheological properties of GelMA: photocrosslinking process and storage modulus G’ after curing (oscillation time scan: strain 1%, angular rate 5 rad/s; light source: 405nm, 30mW/cm2, 30s)

Fig 5. Compressive properties of GelMA: EFL-LS-1601-405 light source curing 30s

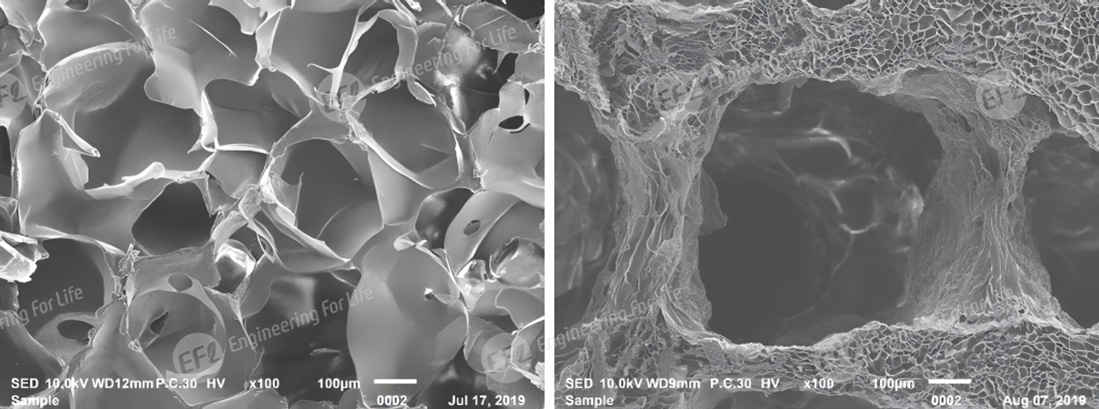

Fig 6. Electron microscopic diagram of hydrogel freeze-dried sample. Left: casting hydrogel SEM; Right: 3D printed hydrogel scaffold SEM

GelMA has been widely used for 2D/3D culture of stem cells, cancer cells, endothelial cells, nerve cells, cardiomyocytes, hepatocytes, chondrocytes and other cells. The cell survival rate is more than 90%, and the cell function is good

Fig 7. Cultivation Effects of Bone Marrow Mesenchymal Stem Cells (BMSCs) on the Surface and Within GelMA

The EFL-GM series hydrogels have high curing speed and adjustable mechanical properties, which are suitable for extrusion bioprinting and projection photocurable bioprinting (DLP). Combined with the multi-functional extrudable 3D bio-printer (EFL-BP-66 series) and the projection photocurable 3D bio-printer (EFL-BP-86 series) independently developed by the EFL team, GelMA complex structure can be easily manufactured, the cell printing survival rate can reach 90%, and the cell function is good.

Fig 8. Projected light curing 3D printing GelMA bionic microstructures: nerve conduit, spinal cord structure, blood vessel structure (top); extrusion 3D printed GelMA complex hydrogel structure: grid holder, ears, nose (below)

Fig 9. Biocompatibility of 3D-printed GelMA scaffold